Metal building ventilation is often one of the most overlooked elements in a metal building design, yet it is one of the most important for long-term performance. A well-planned ventilation system does much more than move air in and out—it actively protects your steel building from moisture damage, improves indoor air quality, and reduces the strain on heating and cooling systems. Without it, even the strongest steel structure can face condensation problems, corrosion, and higher operating costs.

Whether your goal is to keep a workshop comfortable, maintain healthy airflow in a livestock barn, or build one of our Prefab Steel Building Kits with energy efficiency in mind, choosing the right metal building ventilation system is essential. In this guide, we will walk through the different types of steel building vents, how to match ventilation solutions to your building’s purpose and climate, and the maintenance practices that keep your investment performing for decades.

Don’t Sweat It! Why Ventilation is Non-Negotiable

Protecting the Structure

Steel is strong, but it is not immune to moisture. Without proper airflow, condensation can build up on framing, insulation, or even stored equipment. Over time, this accelerates corrosion, reduces the lifespan of your building, and can even affect structural integrity.

Improving Indoor Air Quality

Ventilation replaces stale, humid, or contaminated air with fresh outdoor air. For livestock barns, shops with welding fumes, or storage buildings, good airflow is critical to the health and safety of people and animals.

Saving Money on Energy

Efficient airflow helps stabilize indoor temperatures, meaning your HVAC system does not work as hard. In summer, ventilation removes excess heat from the roof space; in winter, it reduces trapped moisture. Both lead to lower energy bills.

Preventing Condensation

Moisture is one of the biggest challenges in steel buildings. Without metal building vents to keep air circulating, warm indoor air can meet cold metal surfaces and form condensation. Once water droplets start to collect, insulation can become saturated, leading to mould, odours, and structural damage.

Types of Ventilation Systems for Metal Buildings

Natural Ventilation

Natural ventilation relies on passive air movement. While it may seem simple, its effectiveness depends on achieving a balance of intake and exhaust airflow.

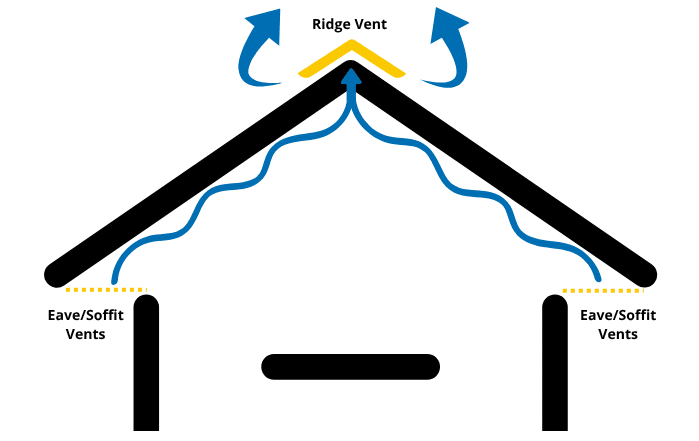

- Ridge Vents: Installed along the roof peak, ridge vents let hot, humid air escape naturally. They are most effective when paired with eave/soffit vents.

- Eave/Soffit Vents: Located under the roof overhang, these vents allow cooler, drier air to enter the building. When combined with ridge vents, they create continuous airflow from bottom to top. This setup is especially popular in shed ventilation systems.

- Louvers: Wall louvers, fixed or adjustable, provide cross-flow ventilation. They are cost-effective for garages, barns, or equipment storage.

- Windows: Operable windows add both light and airflow, a practical choice for smaller workshops or residential garages.

- Turbine Vents: Wind-driven turbine vents spin to pull warm air upward. They are durable, low-maintenance, and effective for small metal building air vents.

Mechanical Ventilation

While mechanical systems excel at controlling airflow, they also add weight and concentrated forces to the building structure. For many steel buildings, especially large warehouses, manufacturing facilities, or livestock barns—natural airflow alone is not enough. Mechanical systems provide consistent, controlled ventilation to manage heat, humidity, and air quality.

- Exhaust Fans: These actively remove hot or humid air, and are widely used in shops, warehouses, and barns. Fan sizing is based on CFM (cubic feet per minute), which takes into account occupancy, machinery, and internal moisture loads.

- HVAC Systems: In offices, retail spaces, or commercial facilities, full HVAC systems integrate heating, cooling, and ventilation. Engineers calculate both sensible loads (temperature) and latent loads (humidity) to deliver balanced indoor conditions.

Structural Considerations

Unlike natural ventilation, mechanical systems add weight and concentrated forces to the building structure. Roof-mounted exhaust fans, suspended ductwork, and large HVAC units must be accounted for during the engineering stage. These are considered concentrated or point loads because the weight is applied at specific points rather than evenly distributed.

If the building is not designed to carry these loads, problems can arise—from sagging purlins to long-term frame stress. That is why it is critical to work with a supplier like Norsteel that engineers every steel building to handle not only wind, snow, and seismic loads but also the additional structural requirements of mechanical ventilation systems.

Mechanical ventilation is often essential when indoor activities generate high heat, moisture, or fumes, but it must be designed with both airflow needs and structural integrity in mind.

Hybrid Systems

Hybrid solutions combine natural and mechanical systems. For example, a warehouse may rely on ridge and eave vents most of the year, with exhaust fans activated during peak summer heat. This approach offers both efficiency and flexibility.

Spot Ventilation

Targeted ventilation addresses high-risk zones such as welding bays, washrooms, or chemical storage. Spot exhaust fans prevent fumes and humidity from spreading throughout the building.

Choosing the Right Ventilation for Your Steel Building

The right solution depends on several factors:

- Building Use: A small backyard garage can rely on ridge and eave vents, while shed ventilation systems often benefit from this same simple setup. By contrast, an industrial warehouse ventilation system may need hybrid or mechanical systems sized for heavy loads. Agricultural barns often require higher air exchange rates to maintain animal health.

- Building Size: Larger steel buildings trap more heat and moisture, demanding higher ventilation capacity and more air movement points.

- Climate and Location:

– In hot, humid regions, mechanical systems are often required to keep condensation under control.

– In northern climates, cold air meeting warm interiors increases condensation risk, making balanced intake and exhaust critical.

– In dry climates, natural ventilation may be sufficient but still essential to maintain air quality.

Common Ventilation Problems in Your Steel Building

Controlling Moisture and Condensation

Condensation is the top concern in steel buildings, and inadequate metal building ventilation is often the root cause. If not addressed, it can lead to rust, mould, and damaged insulation.

Reducing Unwanted Noise

Poorly maintained fans or turbine vents can create rattling noises. Regular inspections and lubrication keep them running smoothly.

Preventing Uncontrolled Air Leaks

Unsealed openings or damaged vents can cause drafts and reduce efficiency. Ensure that all metal building vents are properly fitted and sealed.

Your Essential Ventilation Maintenance Checklist

- Semi-Annual Inspections (Spring & Fall): Check ridge vents, louvers, and fans for blockages or damage.

- Clean & Lubricate Moving Parts: Turbine vents and fans should spin freely to remain effective.

- Adjust Fan Speeds and Vent Openings Seasonally: Increase airflow in humid summer months, reduce it in winter to maintain warmth while still controlling condensation.

- Inspect Insulation and Vapor Barriers: Ventilation works hand-in-hand with these systems to prevent condensation, so make sure they are intact and performing as designed.

Build Better with Norsteel

At Norsteel, we understand that strong buildings are built on details. Ventilation is more than an accessory—it’s a core part of steel building performance. That is why every Norsteel building is designed and engineered to accommodate the ventilation system best suited to your project, whether natural, mechanical, or hybrid.

By planning for ventilation requirements from the outset, we ensure your building can support ridge vents, eave vents, or even heavier mechanical systems that impose concentrated or point loads on the frame. With nearly 40 years of expertise, we deliver pre engineered steel buildings that withstand environmental demands like wind, snow, and seismic loads, while also providing the flexibility to integrate the ventilation system that keeps your space efficient, comfortable, and built to last.

FAQs

What is the most common type of ventilation for a metal garage?

The most common setup is ridge vents paired with eave/soffit vents. This creates a natural airflow cycle without requiring electricity.

What is the best ventilation for a metal building?

There is no single answer. Small sheds or garages work well with natural airflow, while large or specialized buildings may require mechanical or hybrid steel building ventilation systems.

What are the three methods used to ventilate a building?

Natural ventilation, mechanical ventilation, and hybrid systems.

Do I need ventilation in my steel building if I live in a mild climate?

Yes. Even in mild climates, moisture and stale air can accumulate. Ventilation ensures a fresh, dry environment year-round.

What are the ventilation requirements for a metal roof?

A balanced system of eave (intake) and ridge (exhaust) vents ensures continuous circulation across the roof line.

Can I add ventilation to an existing metal building?

Absolutely. Louvers, turbine vents, or exhaust fans can be retrofitted into existing structures to improve airflow.

How does ventilation affect the energy efficiency of my building?

By reducing trapped heat and humidity, ventilation lowers the building’s energy loads, making HVAC systems run more efficiently and reducing utility bills.

What ventilation is best for an industrial warehouse?

Hybrid systems combining ridge/eave vents with exhaust fans are often the most effective. They can handle high heat and moisture loads while keeping energy use in check.

How to ventilate a metal barn?

Ridge and eave vents provide steady airflow, while mechanical fans are often added in livestock barns to manage humidity and odors.

Do I need a vapor barrier in my metal building?

Yes. Vapor barriers work alongside ventilation to stop warm indoor air from condensing on cold steel surfaces.

How to stop condensation in a metal building?

Use balanced intake and exhaust vents, install insulation with vapour barriers, and ensure the slab or foundation prevents moisture from rising.

What can you spray on metal to stop condensation?

Anti-condensation coatings exist, but they are typically short-term measures. For lasting results, proper ventilation, insulation, and vapour barriers remain the most reliable solutions.

How to stop condensation on steel beams in winter?

Maintain proper airflow with steel building vents, use insulation and vapor barriers, and address high-risk areas with spot heating if needed.