If you’re thinking about insulating your metal building or structure, there are a few factors to consider. You know you want to keep the cool air in during the summer, and the warm air in during the winter, but what kind of insulation should you use? Do you need a vapour barrier? And just what is an R-value?

Norsteel has enlisted the help of metal building insulation-expert, Robert Tiffin, National Accounts Manager for the industry-leading insulation manufacturer Silvercote, to help describe some of the common forms of metal building insulation. Continue reading below for an overview of everything you need to know when it comes to insulation for metal buildings.

What is Insulation?

Insulation is any material used to cover, line, or separate which also prevents or reduces the passage, transfer, or leakage of heat, electricity, or sound. There are many types of metal building insulation available on the market, but depending on your local energy codes and the intended use of your structure, you may be forced to use a particular form of insulation. Whether it is for your agricultural steel building or industrial or other uses, it is important to understand the main types of insulation.

There are four main types of insulation used in metal building structures:

Glass wool (aka Fiberglass)

- Made from fine glass fibers, typically formed into blankets or batts with a wool-like texture. It’s cost-effective and easy to install, making it the most common insulation for pre-engineered steel buildings.

Mineral wool

- Composed of spun rock or slag fibers, mineral wool offers higher fire resistance and soundproofing properties than fiberglass. It is often used in fire-rated assemblies.

Spray foam

- Formed by combining two liquid components (isocyanate and polyol resin) that expand into a solid foam upon application. Spray foam provides excellent air sealing and thermal performance, but not all metal buildings are engineered to support its application—check with your building provider.

Polyisocyanurate (sometimes called “Poly-iso”) rigid board insulation

- A high-performance (high-R-value), closed-cell foam insulation that provides excellent thermal resistance and is often used in roofs or as continuous wall insulation, especially in space-limited applications.

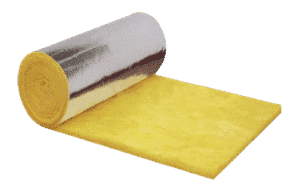

Fiberglass insulation with a foil facing.

As mentioned, depending on compliance requirements in your specific climate zone, municipal or regional codes may call for combinations of insulation products including faced glass wool and poly-iso rigid board. If the use of rigid board is cost-prohibitive there are alternative assemblies which meet the requirements of the standard/code.

What is Facing?

Put simply, facings are barriers which are attached to insulation to protect the surface of the insulation, hold it together, or act as a vapour retarder (see image above of fiberglass insulation with a foil facing).

Most commonly however, manufacturers attach a facing to act as a vapour barrier and/or air barrier. Facings are engineered to protect insulation from physical abuse, control moisture migration, and where necessary to meet fire codes and standards. Vapour retarders can be composed of vinyl, polypropylene, polyethylene, foil, or metalized polyester.

Why Insulate My Metal Building?

In simple terms, metal building insulation will help keep the heated interior space warmer in the winter, and air-conditioned spaces cooler in the summer. Regardless of where you live, if you plan on using your metal building for human occupancy of any kind, it is generally recommended insulation for metal buildings.

Here are just a few potential benefits that come from insulating your metal building:

- Insulation improves temperature regulation by reducing heat transfer through the roof and walls. In cold weather, it slows heat loss; in hot weather, it minimizes heat gain. This helps maintain a more stable interior temperature year-round, keeping the environment more comfortable for people, animals, or equipment—especially important for climate-sensitive applications like workshops, storage units, or agricultural facilities.

- Since insulation creates a thermal barrier, it also reduces energy costs in climate-controlled metal buildings because the heating and cooling systems do not have to work as hard. This lowers energy consumption and improves overall efficiency—saving you money month after month.

- Insulation prevents moisture condensation. When temperature and dew-point are at the right combination, you will have condensation build up on your building’s roof and walls. This could result in water raining down in your building.

- Insulation helps with acoustical performance, reducing noise levels. Most forms of insulation have acoustical and sound absorption properties which reduce interior reverberations and prevent transmission from exterior.

- Insulation helps maximize your return on investment (ROI). The insulation acts as a barrier between metals, that in the presence of condensation could otherwise lead to rusting.

Mineral wool insulation

Spray foam insulation

Poly-iso board insulation

Oh, and What is an R-Value?

R-value refers to the ability of the insulation to resist thermal transmission (conductive heat flow). The higher the R-value, the greater the insulating effectiveness.

Single and multi-layer faced and unfaced cavity fill glass wool is the most typical seen in conventional construction. (R2.9 – R3.8 per inch (25.4 mm)). By far the most common type of insulation sold for prefab steel building systems, is fiberglass laminated blanket insulation. Easy to install and cost effective, blanket insulation is available in several R-Values for both roof and walls.

Mineral wool is primarily composed of basalt (volcanic/igneous rock), and commonly used in fire-rated wall assemblies. It has a higher R-value per inch than glass wool. (R3.0 – R3.3 per inch (25.4 mm)).

Poly-Iso board has a high R-value per inch so is good for use when needing a consistent, uncompressed or continuous insulation where limited space is available. (R6.2 per inch (25.4 mm)).

Spray foam insulation materials can be sprayed, foamed-in-place, injected, or poured. Foam-in-place insulation is blown into wall cavities to insulate and reduce air leakage. Some installations can yield a higher R-value than traditional insulation for the same thickness, and can fill even the smallest cavities, creating an effective air barrier. (R3.6 – R4.3 per inch (25.4 mm)).

One of the most common questions we receive is how to insulate a metal building to make it livable in extreme climates, such as -40°C conditions. With the right insulation package and building design, it is absolutely possible to maintain a comfortable interior temperature, even in harshest winters.

At Norsteel, we offer two standard metal building insulation packages:

- Low R-Value – single layer blanket insulation: R20 6” blanket on walls of the building and the roof

- High R-Value – Cavity-Fill + Single Layer Blanket insulation: Up to R28 on roof and wall

Speak with your metal building manufacturer for their recommendations, as factors such as energy codes, cost, installation techniques should all be considered before making your decision.

Contact Norsteel Today!

Today’s Pre-engineered steel buildings are energy efficient by design, engineering and construction. They are used for a multitude of unlimited purposes from residential steel buildings to storage and more. This dictates that every prefab metal building system has individual requirements in terms of insulation. Pre-engineered metal buildings are compatible with several insulation options. All of these increase thermal efficiency and provide sound resistance.

Whether you are only interested in accounting for condensation, or whether you are heating a retail outlet or restaurant; it is important to discuss your heating and cooling requirements with your Norsteel Building consultant. This will help you explore the best options and understand how to insulate a metal building properly.

If you’re considering insulation for metal buildings, you need a team of experts who can help navigate functionality, costs, and local building requirements. When you engage Norsteel we become your partner throughout the entire construction process. Contact us today for a free, no obligation quote on your next building project!

FAQs

How to Insulate a Metal Building?

Insulating a metal building starts with choosing the right insulation type for your climate zone, energy code, and building use. Common types include fiberglass (glass wool), mineral wool, spray foam, and polyisocyanurate (Poly-iso) rigid board.

Installation typically involves placing insulation between the framing and metal panels, often using faced fiberglass batts with a vapour barrier like foil or polypropylene. For more effective thermal performance, consult your metal building manufacturer – some systems require specific installation techniques or assemblies to comply with local codes.

Will insulating my metal building reduce energy costs?

Yes, proper insulation reduces the amount of energy needed to heat or cool your space, resulting in lower utility bills over time. Insulation helps maintain consistent indoor temperatures by reducing thermal transfer, which improves HVAC efficiency and lowers overall operational costs – especially important for conditioned buildings used for offices, workshops, or retail.

How do I prevent condensation in a metal building?

Condensation forms when warm, moist air meets a cooler metal surface. Insulation helps regulate the temperature difference between indoor and exterior surfaces, significantly reducing condensation risk. Adding a vapour barrier or using faced insulation (e.g., foil-faced fiberglass) creates an effective moisture control system that protects your structure from interior rain, mold, and corrosion.

Is insulation necessary in mild climates?

Even in milder climates, insulation adds value. While you may not need extreme thermal resistance, insulation still helps with moisture control, noise reduction, and long-term building protection. If the building is used for human occupancy, insulation is recommended regardless of location to enhance comfort and protect internal equipment or products.

What happens if I don’t insulate my metal building?

Without insulation, your metal building may experience:

- Higher energy costs due to poor thermal performance

- Condensation problems, leading to rust and water damage

- Uncomfortable indoor temperatures year-round

- Poor acoustics from sound echoing

- Shorter lifespan of building components due to unchecked moisture and temperature extremes

Skipping insulation might lower upfront costs but can lead to expensive repairs and inefficiencies later.

How long does insulation last in a metal building?

The right answer to this is it depends. Insulation in metal buildings can last for a long time, but the longevity truly depends on the material quality, environmental factors, proper installation and maintenance, and the type of insulation used.

When high-quality insulation is used, it will naturally last longer. Exposure to moisture, pests, and extreme temperatures have an impact on how long insulation lasts. In order to maximize the lifespan of insulation, proper installation can avoid issues of leaks and structural failures and regular inspections can help identify possible issues early on. Additionally different insulations have varying lifespans – for example, mineral wool insulation can potentially last the lifetime of the building whereas some other methods may not.