If you are planning on insulating a metal building, you might already know the basics, like keeping the warm air in during winter and the cool air in during summer. But when it comes to choosing the right insulation system, things can get a bit more complex. While the basics are discussed in the blog Metal Building Insulation, let’s break down some of the more advanced insulation options and requirements you might encounter when insulating your steel building.

Choosing the Right Insulation System

Blanket insulation is one of the most popular choices for steel buildings—and for good reason. It’s cost-effective, easy to install, and works well for most standard applications. But if you’re looking for something more efficient, the Energy-Saver System could be the game-changer you need.

Single Blanket Insulation: A Reliable Standard

One of the most common and cost-effective insulation methods, Single Blanket Insulation uses flexible rolls of fiberglass which is simply rolled on top of the structural members, covered with the roof or wall cladding, and screwed into place. It is easy to install and suitable for a wide range of applications.

Key Features:

- Thermal Efficiency

Helps maintain comfortable interior temperatures and reduces heating/ cooling costs - Moisture Control

With vapor barriers, it reduces condensation buildup, preventing interior water damage - Acoustic Performance

Diminishes sound reverberation and transmission, reducing noise levels

Blanket insulation comes in R-values as low as R8 which can be used to prevent condensation in buildings that are not going to be heated. A typical insulation package for our EasyBuild Model is an R13, 4” blanket insulation on the Walls of the building and an R20, 6” insulation on the Roof. Single Blanket insulation is an ideal solution for low frequency buildings used for garages, storage, and light work areas.

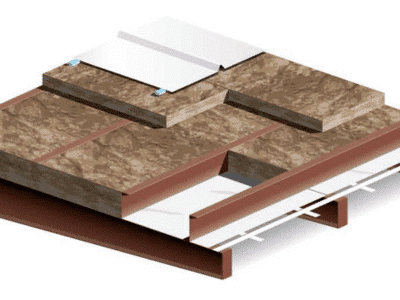

Energy-Saver Systems: A High-Performance Upgrade

The Energy-Saver System combines blanket insulation with a Cavity Fill layer that increases the R Value on any building, including the EasyBuild. This system allows us to boost energy efficiency and achieve R Values up to R60 for Roof and R50 for Walls. In such cases, additional insulation is installed in between the girts and purlins, thereby “filling the cavity” and increasing the overall R-Value. In some cases, the girts and purlins of the building are made deeper, so that there is a larger cavity to accommodate the higher R-Values.

Key Advantages:

- Optimized R-Values

Achieves higher thermal resistance for code compliance - Air Tightness

Reduces air leakage for improved energy efficiency - Durability

Resistant to wear, mold, and mildew - Aesthetic Appeal

Provides a clean, finished look for exposed ceilings

Best Way to Insulate a Metal Building: Key Considerations

The best way to insulate a metal building depends on how you plan to use the space, your local building codes, and your long-term performance goals. Whether you’re building a garage, workshop, or commercial unit, the right insulation system will help you maintain comfort, reduce energy costs, and protect your investment over time.

Start by identifying whether your building will be heated, cooled, occupied year-round, or used for storage only. This will determine the level of insulation required and whether you need to meet energy efficiency codes like Ontario’s SB-10.

Some key considerations before choosing an insulation system:

- Building Usage: Occupied buildings, especially those used for offices, workshops, or livestock, often require higher R-values and stricter air/vapour control than non-conditioned structures like storage units.

- Roof Type: Standing seam roofs are better suited for higher insulation values and continuous insulation applications.

- Local Energy Codes: Compliance with standards such as SB-10 or IECC will impact your choice of insulation type and installation method.

How to Install Insulation in a Steel Building

Wondering how to insulate a metal building efficiently and without delays? It all starts with early planning and the right guidance.

Importance of Installing During Building Assembly

Installing insulation during the erection of your steel building is essential, especially for the single blanket system. The blanket insulation, which is 6 inches thick, must be rolled over the purlins and girts before the roof and wall cladding is secured. This ensures proper alignment, full coverage, and optimal thermal and moisture performance.

Energy-Saver Systems, which combine the single blanket with cavity fill, are most effective when installed during building assembly, as this approach improves efficiency and helps reduce overall labour costs.

Installing during assembly helps:

Minimize material waste and installation errors

Preserve the integrity of vapour barriers and insulation layers

Ensure proper fit around girts, purlins, and other structural elements

Improve energy performance and lower long-term maintenance costs

Insulation Upgrades After Assembly

While early installation is always recommended, additional cavity fill insulation can be added after the building is erected to increase the R-value. This second step in the Energy-Saver system involves filling the space around purlins and girts with extra insulation, enhancing thermal performance for projects that require improved energy efficiency over time.

In projects with tight timelines, it is common to install the single blanket during assembly and complete the Energy-Saver upgrade afterwards. This two-step approach is how to insulate a steel building when speed is a priority, allowing for flexibility without compromising results.

It is also worth noting that certain insulation systems—like fire-rated wall assemblies using Rockwool—are not optional upgrades, but rather code-driven design requirements. These systems must be planned during the design phase and installed during construction to meet fire resistance standards such as 1-hour or 2-hour fire ratings.

Whether you are using standard blanket insulation, adding cavity fill for energy upgrades, or meeting fire-rated wall requirements with Rockwool, early planning and installation set the stage for long-term durability and performance.

Overview of the Process

The exact installation process depends on your chosen system, but typically includes:

- For the single blanket system, placing blanket rolls over the purlins and girts before the roof and wall cladding is secured.

- Installing vapour barriers or facings to manage condensation and air leakage.

- For Energy-Saver systems, inserting additional cavity fill between members to achieve higher R-values.

- In fire-rated assemblies, following the design specifications for mineral wool, girts, and steel liners.

Norsteel delivers all insulation pre-cut, colour-coded, and clearly labelled, according to its specific installation zone. Each roll is packaged in a thick plastic bag and comes with a placement diagram to simplify the process ensuring a smoother installation and reducing the chances of on-site errors.

Tools and Tips

- Use insulation knives or shears for accurate cuts

- Wear proper protective equipment when handling glass wool or mineral wool

- Ensure insulation is dry and stored properly until installation

- Organize labelled rolls according to their installation zones to improve speed and accuracy

Insulation Installation Manuals

To support your crew during construction, installation manuals for our insulation systems are available on our Manuals page. We provide detailed guides for:

Energy-Saver Wall and Roof assemblies

Simple Blanket Wall and Roof assemblies

Following best practices and using the correct tools will help you avoid costly mistakes when insulating a metal building of any size or use.

Meeting SB-10 Requirements

When you are planning your new Metal Building System, or even if you intend to add an extension to your existing structure, you need to ensure that you are in compliance with the SB-10 energy efficiency codes. SB-10 is the section of the Building Code that dictates the energy efficiency requirements for buildings and includes performance requirements for heating, cooling, ventilation, hot water systems, and even lighting. SB-10 requirements are essential for getting your building permits approved, and they vary depending on your building’s size, application, and location. In some cases, meeting these standards might require design changes, like switching to a Standing Seam Roof to allow for higher R-values.

SB-10 matters because it ensures your building is energy-efficient and compliant with local laws. Investing in an insulation package that meets these standards will save you headaches down the road—think lower energy costs and fewer retrofits. Our team at Norsteel can help you navigate these requirements and make sure your building is up to code.

Fire Safety with Rockwool Insulation

When fire safety is a priority, Rockwool, (aka Mineral wool) insulation is your go-to solution. This mineral-based insulation provides excellent fire resistance, offering ratings of one or even two hours, depending on the application. For steel buildings, this is a reliable way to meet fire safety codes while maintaining the structural integrity of your space. The design of the metal building system changes to accommodate the fire rated wall.

SB-10 matters because it ensures your building is energy-efficient and compliant with local laws. Investing in an insulation package that meets these standards will save you headaches down the road—think lower energy costs and fewer retrofits. Our team at Norsteel can help you navigate these requirements and make sure your building is up to code.

Following W605 requirements, in the case of one-hour fire-rated walls, we add girt lines at 4’ centers, a sealed 24-gauge liner and two 4” layers of Rockwool in the cavity.

Achieving a two-hour fire-rating is similar. Following W606 specifications, the building is designed with girt lines at 4’ and both the interior liner as well as the exterior cladding must be 24-gauge steel. The liners are sealed and again, the cavity is filled with two layers of 4” rockwool insulation.

What does this mean for you? Peace of mind. Whether you are insulating warehouse steel buildings, an office, or a backyard barn dominium, Rockwool helps protect your investment and ensures safety for occupants.

Insulation for Steel Buildings: What to Expect Long-Term

Insulating your steel building is one of the smartest long-term choices you can make—financially, structurally, and environmentally. When you invest in insulation steel buildings, you’re not just solving a short-term issue, you’re making a decision that impacts performance, longevity, and efficiency well beyond thermal comfort.

Energy Savings

Well-installed insulation can significantly reduce long-term energy use, especially in buildings that rely on heating or cooling systems year-round. This not only helps lower monthly utility bills but also ensures better comfort and climate control for occupants or stored goods. Proper insulation also reduces strain on HVAC systems, improving their efficiency and extending their lifespan.

Maintenance

Quality insulation systems help protect your building from condensation-related issues such as corrosion, mould, and material degradation. Vapour barriers maintain internal moisture control, while high-quality materials like fiberglass and mineral wool require minimal upkeep once installed.

ROI and Resale Benefits

Energy savings add up over time, supporting a strong return on your initial investment. A well-insulated steel building is often viewed as a more complete, high-value asset. Whether you plan to sell, lease, or continue using it long term, insulation helps reduce operating costs and increases appeal to potential buyers or tenants.

Environmental Considerations

By reducing energy use, insulation contributes to a lower environmental footprint. Many insulation products are recyclable or made from recycled content, and high R-values help support sustainability goals or future green building certifications.

Partner with Norsteel for Expert Insulation Advice

At Norsteel, we know that every steel building is unique. That is why we take the time to understand your specific needs, whether it is maximizing energy efficiency, meeting strict building codes, or ensuring fire safety. From blanket insulation to advanced systems with Energy-Saver and Rockwool insulation, we have got you covered when it comes to insulating a metal building.

Contact us today for expert guidance and a free, no-obligation quote on insulation steel buildings. Our team will help you choose the right system and determine the best way to insulate a metal building for your project.

Let’s make your steel building stronger, better, and built to last!