In our previous blog series, we examined the permit process and early planning stages of a new construction project. We reviewed the documents required to begin planning a steel building and why it is best to get started early—so your project is ready when it is time to break ground.

Now, we turn our attention to the next step in the build process: the foundation system of metal buildings. In this blog, we will explore what foundations do, how they interact with Steel Buildings, and what types are most commonly used.

What is a Foundation and Why is it Important for Steel Buildings?

Simply put, a foundation is the lowest load-bearing part of a building, typically installed below ground. Although foundations are not included in your typical steel building package, every building system must be constructed on top of one.

For this reason alone, you should have a general understanding of what a foundation is and what role it plays in the overall structure of a building. It’s also important to understand how a foundation will impact the overall cost of your structure.

Do Steel Buildings Need a Foundation?

The foundation connects your steel building to the earth and plays a vital role in the stability, alignment, and long-term durability of the structure.

A poorly designed or installed foundation can lead to cracking, shifting, warping, or moisture issues—jeopardizing the building’s safety and longevity.

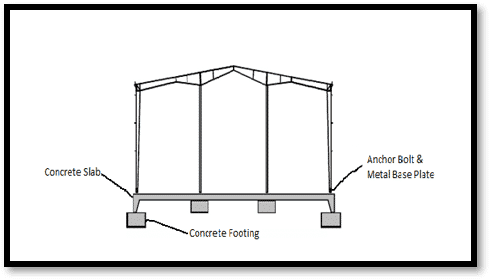

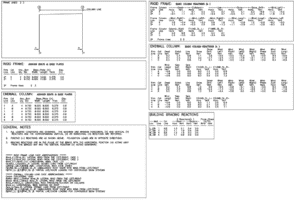

The foundation required in the erection of a Pre-Engineered building generally involves a concrete slab with concrete footings (see adjacent image).

The footing is extra concrete, usually rectangular in shape, poured and formed under a column or some other structural support member of the building. A footing distributes the load carried by the building system support members into the supporting soil.

Connecting Structure to Foundation

When you order a metal building system, the structure is engineered to meet the building codes and environmental loads specific to your site.

As part of this, careful calculations are made to identify the concentrated loads at each spot where a column meets the floor of the foundation.

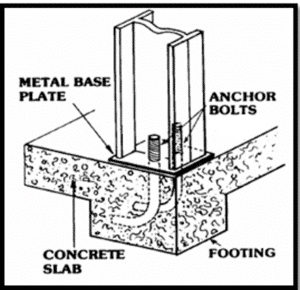

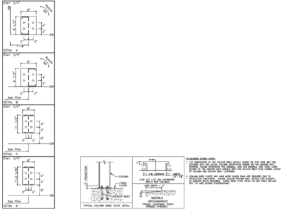

At each of these points, a metal base plate is used to connect the column to the foundation. The base plate is pre-punched to fit over anchor bolts, which are embedded in the concrete.

These connections are critical to transferring the building’s loads to the ground safely and efficiently.

The diagram above details how a single column is connected to the foundation (Left). This is an example of a base plate; where a column is connected to the underlying foundation (Right).

Who Designs the Foundation?

Just as your steel building must be designed and stamped by a certified structural engineer, your foundation must also be designed and stamped by a foundation engineer who is specialized and certified for your specific area.

After your steel building is engineered, you will receive a permit drawing package containing:

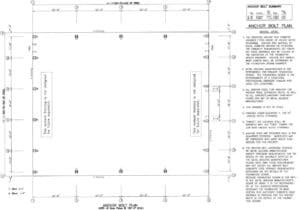

- Precise anchor bolt locations

- Building reaction data (specific loads at each column)

This anchor bolt layout drawing shows exactly where each column will meet the ground.

Each metal base plate connects to the foundation with anchor bolts – this drawing shows the required diameter.

Calculations are made regarding the precise concentrated loads at each spot where a column meets the floor.

You will take the permit drawings for your building, to a foundation engineer who will design a foundation to meet the requirements of your specific structure and site location.

There are different choices for your foundation. Together with your foundation engineer, you will determine which foundation can support concentrated column loads and to protect your structure from shifting soil, moisture, frost, and seismic activity.

How To Create a Metal Building Foundation

If you are considering erecting a metal building, the first step is ensuring the site is ready and your foundation is built to support the structure above.

Not only is the foundation a crucial piece of how strong and rigid the metal building will be, but the foundation will also help protect the metal components from corrosion and other damage as a result of excess moisture or water.

That said, while you can certainly try it yourself, it is often best to hire a concrete contractor to do the work for you. After all, problems with a foundation can jeopardize the integrity of any building that sits on top, and that could be a real danger for the equipment or people inside.

In addition to following industry standards and best practices, a contractor experienced in laying foundations will also help you avoid common pitfalls and give your new building the best chance of standing the test of time.

Before You Build: Permits and Planning

But before any work can start, you will need to secure a building permit first. A building permit is what allows you to create that metal building foundation, as well as erecting the building that sits on it.

If you neglect this step, you could end up facing fines and other penalties, and you may even be required to tear down a significant part of it, or even the entire building.

That is because inspections and the permitting process can be extensive, and if you just barrel ahead and hope to figure it out later, it can mean significant backtracking, if not an eventual reboot of the entire project.

Once you have secured the building permit, the next step is to decide on foundation plans for steel building like where the building will go and the exact footprint of the building.

To keep things simple, and especially if you are using one of our pre-engineered steel building kits, you will want to stick to classic rectangular designs instead of going with something more complicated.

Keep in mind that things like soil and drainage are important when it comes to the longevity and integrity of your metal building and its foundation, so make sure you get the opinion of a professional and exhaust all avenues and options before moving forward.

After the foundation cures, you will be able to start assembly up top. However, keep in mind that improper curing can reduce the strength of your foundation by up to 50 percent, jeopardizing the integrity of the building itself.

Types of Foundations for Steel Buildings

Before choosing a foundation type, the site must be properly prepared. This typically begins with hiring surveyors to stake the building layout and clearing the land of any trees, shrubs, rocks, or debris.

Professional contractors can assist with grading and levelling the site, which is essential for determining whether a concrete slab or a ground-mounted foundation system is the right fit for your structure.

Slab-on-Grade Foundation

The most common choice is a traditional slab-on-grade foundation—a floating concrete slab with underground footings that extend below the frost line.

Slab-on-grade foundations are ideal for many steel building projects, especially those that do not require a full basement or crawl space. This traditional steel building foundation generally involves a concrete slab with concrete footings.

The footing is extra concrete, usually rectangular in shape, poured and formed under a column or some other structural support member of the building.

The footing distributes the load carried by the building system support members into the supporting soil. This type of foundation is often used in both residential and commercial steel buildings.

Key Features:

- Solid concrete slab that acts as the base for the steel structure.

- Underground footings that prevent the slab from shifting or cracking.

Suitable for buildings on level ground, where excavation and grading are minimal.

While slab-on-grade foundations are a traditional and reliable option, they can be labor-intensive and require significant preparation and cost. Additionally, they may not always be the most environmentally friendly option, as they may disturb the land more than necessary.

It is important to note that traditional slab-on-grade foundations are not a DIY project; they require a professional to ensure precision and structural integrity.

While slab-on-grade foundations are a traditional and reliable option, they can be labor-intensive and require significant preparation and cost. Additionally, they may not always be the most environmentally friendly option, as they may disturb the land more than necessary.

It is important to note that traditional slab-on-grade foundations are not a DIY project; they require a professional to ensure precision and structural integrity.

Pier Foundation

A pier foundation uses a series of vertical concrete piers installed below the frost line to support your steel building’s structural columns. This system concentrates the load at specific points, minimizing the need for full slab excavation. It is especially useful for sites with uneven terrain or poor soil conditions, where a slab would be impractical or cost-prohibitive.

Piers are usually poured into pre-dug holes using cylindrical forms known as Sono Tubes (a common brand of fiber concrete forms). These piers are typically reinforced with rebar and engineered to meet frost depth requirements.

For most steel buildings, the piers are connected by a reinforced concrete grade beam that ties them together. This added component helps distribute the structural loads, improves lateral stability, and reduces movement from soil expansion or frost.

This foundation type is common for agricultural, storage, and rural buildings where simplicity, cost savings, and minimal site disturbance are priorities.

Key Features:

- Concrete piers installed beneath structural columns

- Often connected by a grade beam to improve load distribution and stability

- Less site disruption and concrete required compared to full slabs

- Suitable for sloped or expansive soil conditions

Pier foundations are not typically used for high-traffic or heavy-load applications but offer an affordable, flexible solution for smaller steel buildings in rural or remote areas.

Screw Pile Foundation

Screw pile foundations use helical metal piles that are driven or twisted into the ground using specialized equipment. These piles act as the load-bearing base for your steel building and eliminate the need for concrete footings or extended curing times.

This system is ideal for remote or northern locations, where frost heave and short construction seasons can cause delays. Screw piles are also a good fit for environmentally sensitive areas since they cause minimal ground disturbance and require no excavation.

Key Features:

- Helical steel piles drilled directly into the soil

- No need for concrete or curing time

- Highly suitable for frost-prone or remote sites

Screw pile foundations provide fast installation and strong anchoring, making them a smart choice for temporary or modular steel building setups.

Grade Beam (Perimeter) Foundation

A grade beam, also referred to as a perimeter foundation, is a reinforced concrete beam that runs continuously around the base of the building.

It often connects to piers or piles and serves to distribute structural loads evenly while reinforcing the outer edges of the building.

This type of foundation is useful in locations where soil movement or poor drainage is a concern. Grade beams also offer added stability for larger steel structures by tying isolated footings together.

Key Features:

- Continuous concrete beam around the building perimeter

- Often combined with piers or piles to manage structural loads

- Designed to handle soil movement or uneven load distribution

Grade beam foundations are well-suited for commercial and industrial buildings or when additional structural integrity is required.

A Note on “Pier and Beam” Foundations

You may come across the term “pier and beam foundation,” especially in residential construction. This system typically consists of concrete piers with horizontal wooden or steel beams that support a raised floor structure.

However, it is not commonly used for pre-engineered steel buildings, which are designed to transfer loads directly from steel columns into footings or piers.

Steel buildings rely on engineered connections that anchor the column base plates directly to the foundation—eliminating the need for intermediate beam spans.

Norsteel’s EasyBuild Foundation Kit

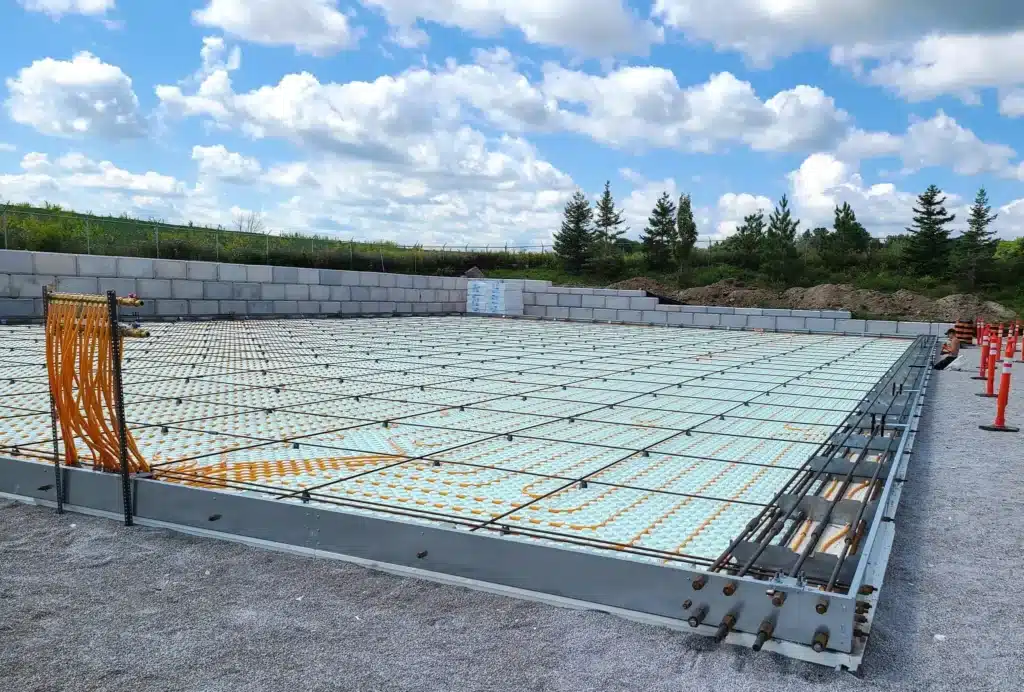

For those looking for a more eco-friendly, cost-effective, and DIY-friendly alternative, Norsteel’s EasyBuild Foundation Kit is an excellent choice. This pre-engineered all-steel floating foundation system is designed for easy assembly and is a suitable match for our DIY steel building kit.

The EasyBuild Foundation is an innovative solution that allows customers to complete their foundation project with minimal hassle, and it is currently one of the most unique offerings in the industry.

Our new foundation system is currently available for structures up to 35’ wide and must be assembled on a prepared level site.

Key Benefits of the EasyBuild Foundation Kit:

- Eco-Friendly Design: The EasyBuild system minimizes site disruption by only removing the topsoil layer during preparation. This preserves the natural soil structure and reduces environmental impact.

- Quick Setup: The pre-engineered components allow for fast assembly, making this a great DIY project for handy customers. Once the site is prepared, the foundation can be assembled in a very short time.

- Robust Stability: The foundation is constructed using high-yield thread bar and precision-engineered Cee-channel framing, providing long-lasting strength and stability for your steel building.

What’s Included in the EasyBuild Foundation Kit:

- Certified Engineered Foundation Drawings: All necessary structural and foundation drawings are included, which streamlines the process for obtaining permits and approvals.

- High-Yield Thread Bar: Provides superior load-bearing strength for the foundation, 30 times stronger than rebar

- Dimensionally stable exterior frame: Delivers a stable, precise foundation for your steel building.

- Anchor Bolt Templates and Hardware: All necessary components for easy and efficient assembly.

- Engineer Certification: Inspection of assembled kit prior to pouring concrete ensures accuracy and compliance with engineered drawings and guarantees structural integrity.

By choosing the EasyBuild Foundation Kit, you not only simplify the construction process but also benefit from an environmentally friendly, cost-effective solution that sets Norsteel apart from other steel building providers.

How to Build a Steel Building Foundation: DIY Installation Process

Building a steel building foundation with the EasyBuild Foundation Kit involves a simple, straightforward installation process that can be completed in just four steps.

Step 1: Site Preparation

First, the site must be prepared by clearing the topsoil and ensuring the ground is level. Removing only the organic soil down to the first level of natural soils or hardpan minimizes the environmental impact. The topsoil is saved and reused for backfill.

Step 2: Install the Gravel Drain Base

Add a minimum of 8” local gravel. Compact the base level, finishing 2” above the existing grade. This is a load-bearing layer, providing drainage, reducing frost action, and creating a smooth surface for paving.

Step 3: Assemble the Foundation Kit

Using the certified engineered drawings and anchor bolt templates, the foundation layout is marked, the Cee-channel framing and high-yield thread bar are installed, and the foundation is securely fastened. This provides the structure for the metal building foundation.

Step 4: Final Inspection and Pouring Concrete

Once the steel framework is in place and we provide the approval certificate, the concrete is poured to create a strong, stable foundation for your steel building.

This four-step process makes the EasyBuild Foundation Kit the ideal choice for DIY enthusiasts who want to take control of their building project while ensuring a high-quality result and alignment with their steel building foundation requirements.

How to Choose the Right Foundation Type

Choosing the right foundation depends on your building’s size, use, and site conditions. Large or heavy-use buildings usually need traditional slab-on-grade foundations for strength and stability. Smaller or lighter buildings might work well with a floating foundation like Norsteel’s EasyBuild Kit.

Soil and drainage are important factors. Stable, well-draining soil allows more foundation options. Poor drainage or frost risk means you’ll need a foundation engineered to handle those challenges. EasyBuild is great for sites where minimizing disturbance is a priority.

Budget and timeline also matter. Traditional slabs often cost more and take longer to install. EasyBuild can be faster and more affordable, especially if you plan a DIY build.

Local building codes and climate affect foundation requirements. Make sure your foundation meets regional rules for frost depth and seismic zones.

If you are unsure which foundation suits your project, contact us. We will help you choose the best option based on your needs and site.

FAQs about Steel Building Foundation

Do steel buildings need a foundation?

Yes, all steel buildings require a foundation. The foundation is the lowest load-bearing part of the building and provides the critical support needed to distribute weight evenly and keep the structure stable and secure.

Without a proper foundation, the building can suffer from shifting, cracking, or moisture damage.

What type of foundation is best for a metal building?

The best foundation depends on your building’s size, use, soil conditions, and budget. The most common type is a traditional slab-on-grade foundation—a concrete slab with footings below frost lines.

For smaller or DIY projects, Norsteel’s EasyBuild Foundation Kit offers a cost-effective, eco-friendly alternative that is easier and quicker to install.

How much does a steel building foundation cost?

Foundation costs vary depending on the foundation type, building size, site conditions, and local labor rates. Traditional concrete slabs usually require more materials and labour, making them more expensive.

The EasyBuild Foundation Kit reduces labor costs and offers a more affordable option, especially for DIY builders.

Can I use an existing foundation for a metal building?

It depends on the condition, size, and design of the existing foundation. A foundation engineer should evaluate whether the current foundation can support the new steel building’s loads and meet local codes.

Often, foundations must be customized for specific building requirements and site conditions.

What is included in metal building foundation plans?

Metal building foundation plans typically include precise anchor bolt locations, footing details, and building reaction data (load calculations at each column).

These plans are engineered and stamped by a certified foundation engineer to ensure compliance with structural requirements and local regulations.