Steel Building Expansions: Precision-Engineered

Need more space on your site but relocating is not the answer? Whether expanding storage, increasing production capacity, or maximizing available property space, Norsteel engineers steel building expansions designed to integrate seamlessly with your existing structure and support long-term growth.

How Norsteel Supports Growth

Whether attaching to an existing Norsteel building or integrating with another steel, masonry, or wood structure on your property, our design process ensures structural continuity, long-term durability, and uninterrupted performance across commercial, agricultural, and residential applications.

Backed by decades of experience in complex steel building projects, the examples below demonstrate how Norsteel translates engineering expertise into fully integrated expansion solutions.

IAMGOLD

________________

Pre-engineered Steel Building Expansion

The client’s existing pre-engineered steel building is distinguished by its unique height and gold finish within the plant. When additional storage and service capacity were required, they turned to Norsteel to engineer a 140′ × 76′ × 73′ truck shop designed to integrate with the original facility.

Although the initial structure was not supplied by Norsteel, the expansion was engineered to match its height, load capacity, and signature gold exterior. The addition aligns at every structural level, increasing service capacity while meeting the demands of an active mining environment.

Crispy Just Baked

________________________________

Hybrid Steel Building Integration

To support increased food production, this client expanded their facility by strategically developing a previously underutilized portion of their site. Norsteel engineered a hybrid steel building designed to connect two existing conventional brick structures, transforming the available footprint into fully operational manufacturing space.

The project required a customized, irregular configuration measuring 128.5′ x 409′ and 167′ x 37.5′, tailored to fill the remaining property area while maintaining workflow continuity. The result is a unified facility that maximizes site efficiency and production capacity.

Pool House

____________________

Residential Steel Integration

This project involved the design and integration of a steel-framed pool house addition attached to an existing residential structure.

The new single-slope building was engineered to connect seamlessly to the home while meeting structural, architectural, and functional requirements.

The steel system provides a durable structural framework for this purpose-built recreational space, demonstrating how steel additions integrate naturally into residential architecture.

Port of Johnstown

______________________________

Custom Integration

This project combined three steel buildings measuring 39′ x 50′ x 41′, 19’6″ x 34’1″ x 41’10”, and 19’6″ x 50′ x 22’4″. The configuration was shaped to fit the available site while aligning with surrounding port infrastructure.

Featuring large doors and strategically placed openings, the facility supports efficient access and logistics movement within the port facility.

SeedMaster

___________________

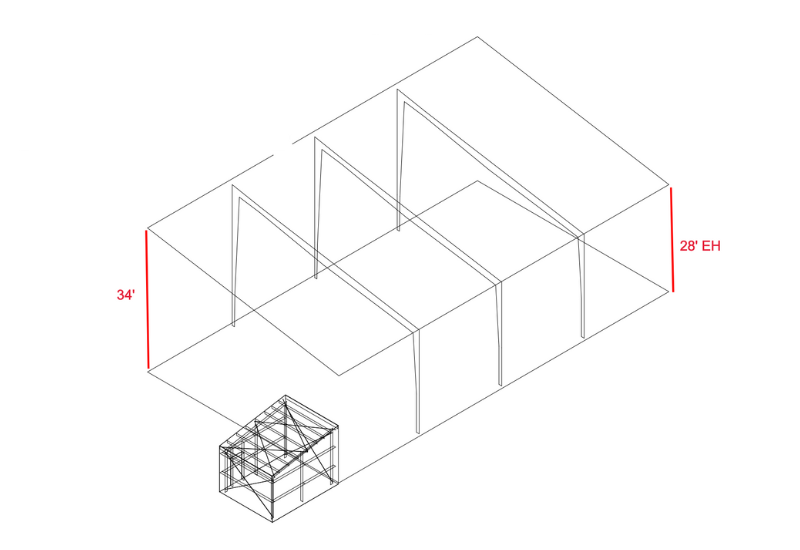

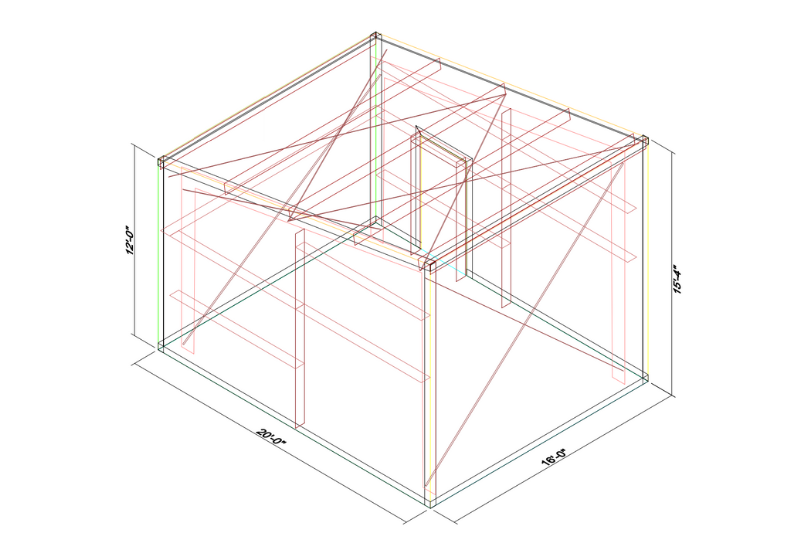

Compact Steel Addition

To support growing storage needs, SeedMaster required a 20′ x 16′ x 12′ single-slope steel addition integrated into their existing 58′ x 100′ facility. While smaller in scale, the project required the same structural analysis, coordination, and engineering precision applied to expansions of any size.

Given the significant height difference between the two structures, the design accounted for snow drift and additional loads generated by the larger building.

Green wall panels were selected to visually match the existing facility, reinforcing architectural consistency while expanding functional space.

Guycan

____________

Multi-Phase Expansion

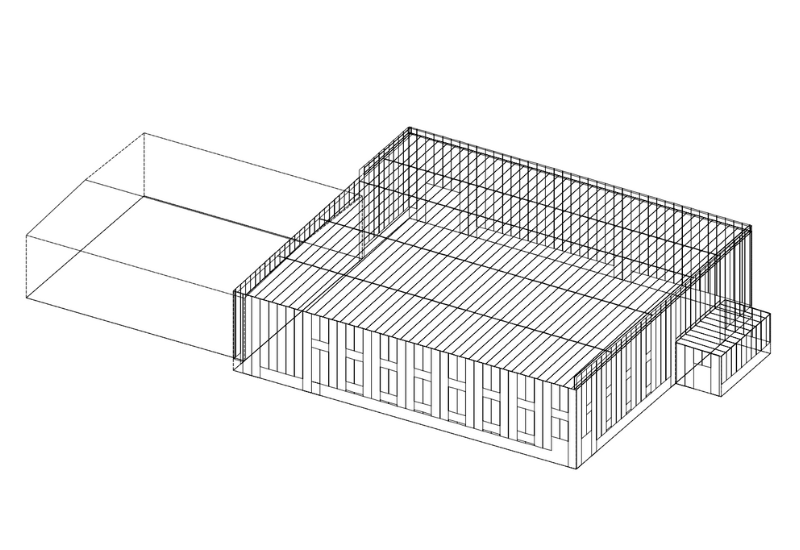

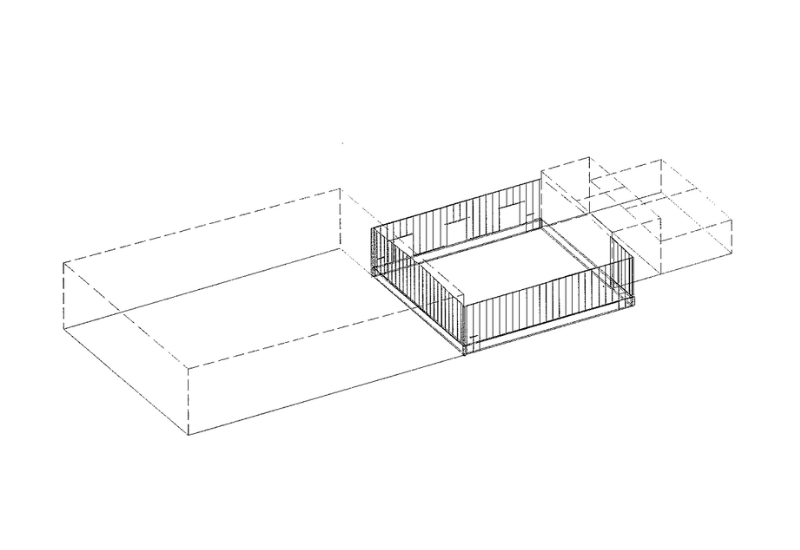

Guycan’s headquarters was developed through a strategic, multi-phase expansion plan, with three pre-engineered steel buildings constructed at different stages of growth.

Each structure was planned with future integration in mind, allowing efficient expansion across the property.

With varying eave heights and elevations, the additions required precise structural alignment to ensure compatibility between phases as the facility evolved.

Beatty Seeds

_____________________

Operational Expansion

To support operational growth, Beatty Seeds required a 120′ x 100′ x 21′ steel building addition integrated into their existing facility. The addition expands usable interior space while optimizing available site area.

The new facility is fully insulated to support thermal performance, structural reliability, and energy efficiency.

Storage Expansion

_______________________________

Conventional Steel Integration

This 99′ x 193′ x 103′ steel building expansion connects to an existing brick and concrete structure, substantially increasing on-site storage capacity while integrating with the original facility. The project includes a mezzanine level that adds usable interior space within the existing footprint.

Through Norsteel’s Best-Fit Approach, the new building was executed using conventional steel elements rather than a pre-engineered system, resulting in a more cost-efficient solution tailored to the project.

Workshop Integration

___________________________________

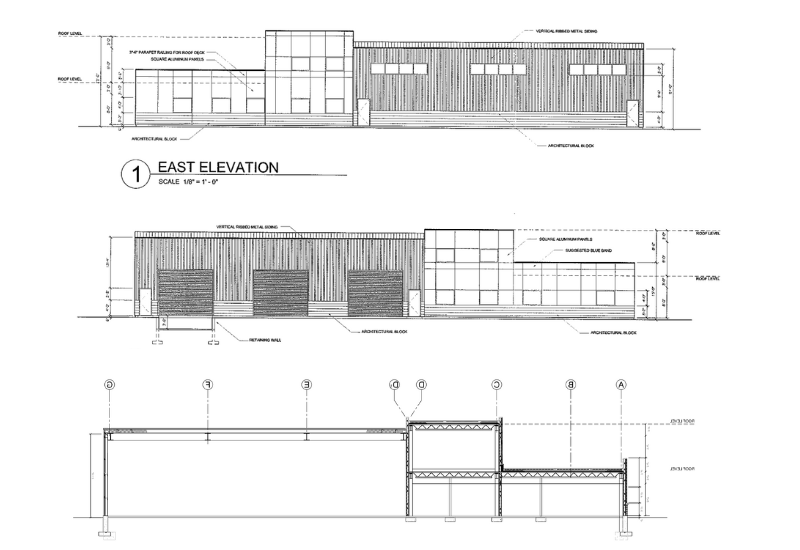

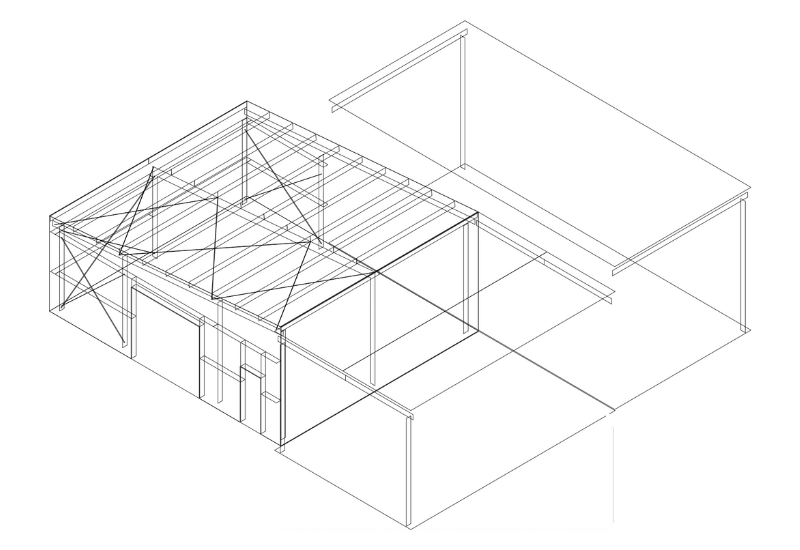

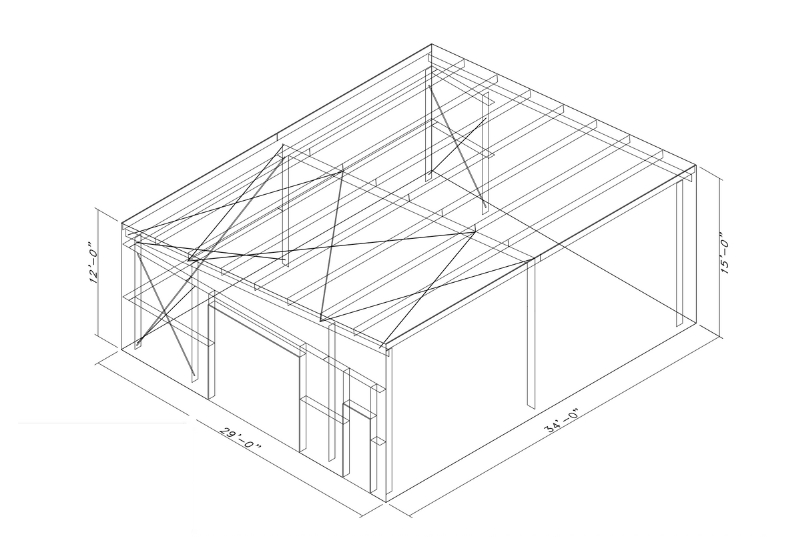

Commercial Addition

This 29′ x 34′ single-slope steel workshop was engineered as a commercial addition, designed to attach to two existing structures along the rear and side of the property.

With eave heights ranging from 12′ to 15′, the addition was developed to complement the property layout while providing a purpose-built space for mechanical operations and equipment storage.

Finished in charcoal wall panels with black trim, the workshop blends seamlessly with the surrounding structures.

Customer Story: Agricultural Extension

Customer Story: Agricultural Extension

“I definitely recommend Norsteel, they really look for the solution that you want. If you want something different, they can design it. This is living proof that they can do it!” – Ferdie Nel, Sheep Farmer

When Ferdie Nel transitioned his sheep farm to dairy production, he needed additional space that would connect directly to his existing building. Norsteel engineered an integrated addition adapted to the site’s terrain, allowing livestock and equipment to move between facilities without exposure to weather.

Growth Demands Smart Expansion

As operations scale, facilities must evolve. Increased inventory, additional equipment, workflow adjustments, or new service lines often require more space, but not necessarily a new location.

For many businesses and property owners, the opportunity lies within their existing footprint. Strategic expansion allows you to maximize underutilized areas of your site, strengthen operational flow, and increase usable space without the cost and disruption of relocating.

With the right engineering approach, new steel structures can be designed to work in harmony with existing buildings and site configurations, unlocking the full potential of your property and converting available space into purposeful infrastructure.

Engineered for Seamless Integration

Expanding an existing facility requires more than adding a new structure alongside what is already built. It demands precise structural coordination between old and new, including load distribution and foundation compatibility to roof alignment, elevation transitions, and updated code compliance.

Norsteel approaches every expansion as a fully engineered integration project. Our team evaluates existing structural systems, site conditions, and operational requirements to ensure the new steel building aligns structurally and functionally with the original facility.

Designed to Support Ongoing Operations

Expansion projects often occur while facilities or properties remain in active use. Norsteel prepares each expansion system with clearly defined connection details, coordinated documentation, and structured delivery timing to support an organized assembly process.

By defining integration requirements before delivery, the assembly phase proceeds with greater predictability, supporting industrial operations, agricultural activity, or residential use throughout the expansion process.

Plan Your Expansion with Confidence

Every expansion begins with a clear understanding of the existing facility and site conditions. Accurate dimensions, elevation information, terrain characteristics, and regional load requirements all play a role in determining how a new structure can be properly integrated.

Providing available drawings, measurements, or relevant site details allows our team to assess your project efficiently and develop a tailored expansion strategy aligned with your operational or property goals.

Here is what happens next:

- Information Review

- Consultation Call or Meeting

- Site & Structural Evaluation

- Tailored Expansion Plan

- Manufacturing & Delivery